Climatic conditions

The correct climatic conditions at the moment of paint application is of great importance for the performance of the paint system as such.

It is widely known that the climate conditions under which a product is applied are of crucial importance for the final quality. Applying products at low temperatures can cause the drying and curing to significantly slow down. When the surface is below the dew point, condensation will occur as a result of which the paint system has poor adhesion to the substrate or to a preceding coat. Condensation is not always clearly visible when the surface temperature is just barely above dewpoint. Factor that may influence the occurrence of condensation are variants in surface temperature or ambient temperature, changes in barometric pressure, shade or exposure to sunlight, etc. A thin film of condensation will negatively influence the adhesion of the coating film to the substrate.

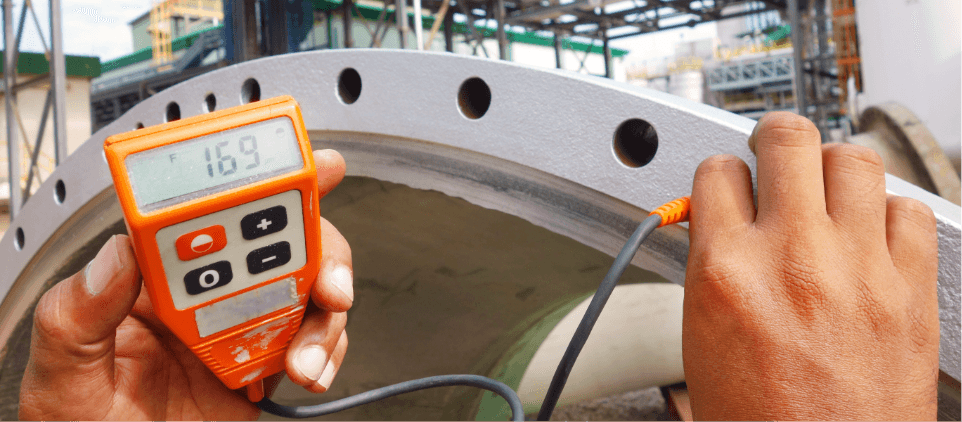

The measuring of climate conditions and the assessment of the results must be performed with great care. DCC has both the knowledge, experience and equipment to accurately measure the climate conditions and surface temperature. Results will be assessed in relation to the coating specification or coating manufacturers requirements.

Common test methods “climate conditions”

Climate conditions are commonly measured suing so called “Multi meters”. These are digital gauges that often have the capability to store measurements for subsequent processing.

Measured are:

- Ambient temperature: the temperature of the surrounding air.

- Relative humidity: the relative level of saturation of the air with moisture

- Dew point: the temperature at which condensation will form

- Substrate temperature: the temperature of the (steel) substrate

- Delta T: the difference between the dew pint and the substrate temperature

A good coating specification will provide guidance with regard to the minimum applicable climate conditions at the time of application of the coating system. It is important to prevent the formation of condensation on the substrate to be painted. To ensure this usually a minimum of +3 degrees difference between the substrate temperature and the dew point is specified. This means that the substrate should always be 3 degrees “warmer” than the actual dew point temperature. This will compensate for possible local differences in surface temperature or humidity.

A property to consider is the fact the these so called multi meters require adequate time to acclimatize to the environment in which the measurements are to be made. The very fact that the gauge will produce numbers that are seemingly “accurate” often leads to the unjust assumption that the readings must be correct. When a gauge has not had sufficient time to acclimatize to the relevant conditions the readings cannot be trusted. For instance when a gauge has been stored inside the booth of a car during winter and readings are taken in, for instance the inside of a heated tank maintaining 10-15 degrees C , it will take up to 30 minutes before the gauge has stabilized and the readings are reliable. The gauge itself, including its sensors, will have to adopt to the temperatures of the general area to be measured before readings become reliable. Another disadvantage of these gauges is that (blasting)dust or overspray may contaminate the equipment and influence the results of the readings. Equipment needs to be calibrated on a regular basis by the manufacturer

A somewhat old fashioned but still very reliable method of measuring climate conditions is the so called “sling psychrometer”. This instrument uses two mercury (or recently alcohol) thermometers. To be able to measure the relative humidity a diagram or chart is used (Mollier diagram). The major advantage is that this gauge does not require any acclimatisation. The gauge is relatively fast and accurate. Verification of calibration is simple, remove the “sock” from the “wet bulb” thermometer and wait for 1 to 2 minutes after which time both thermometers should display the same temperature. If this is the case it may be assumed that they are accurate. To be certain a third thermometer may be used for comparison with the thermometers on the “sling psychrometer”.

In case you have additional questions on the subject of measuring climate conditions during the coating application process call or Email DCC.