Measuring Gloss

The gloss level of a coating system is measured by projecting a ray of light with a constant intensity at a specific angle and subsequently measuring the amount of reflected light at the same angle.

The gloss level of a coating system is measured by projecting a ray of light with a constant intensity at a specific angle and subsequently measuring the amount of reflected light at the same angle. This can be done at different angles, typically 20, 60 and 85 degrees. The angle to be used depends on the level of gloss that is expected to be measured. The 20 degree angle is used for low gloss (low reflecting) surfaces. A typical example would be camouflage colours on military equipment. Semi-gloss of egg shell finishes are measured at an angle of 60 degrees whereas high gloss finishes are measured at an angle of 85 degrees.

The gloss level is expressed in GU or Gloss Units. The practical problem when measuring gloss is that the level is gloss is highly influenced by the degree of texture on the coated surface. A product with a specified gloss level of, for example 85 GU, may when sprayed or rolled with a (light) surface texture or when applied over a previous coat with a surface texture have a measured actual gloss level of less than half of the specified level. The same product, applied without any texture over a perfectly smooth surface, will achieve the specified gloss level. A distinction must be made between the product gloss level, the maximum (theoretical) level of gloss that may be achieved when applying the product over a flat and smooth surface without any form of texture and the actual gloss level of the product applied on a substrate as part of a coating system.

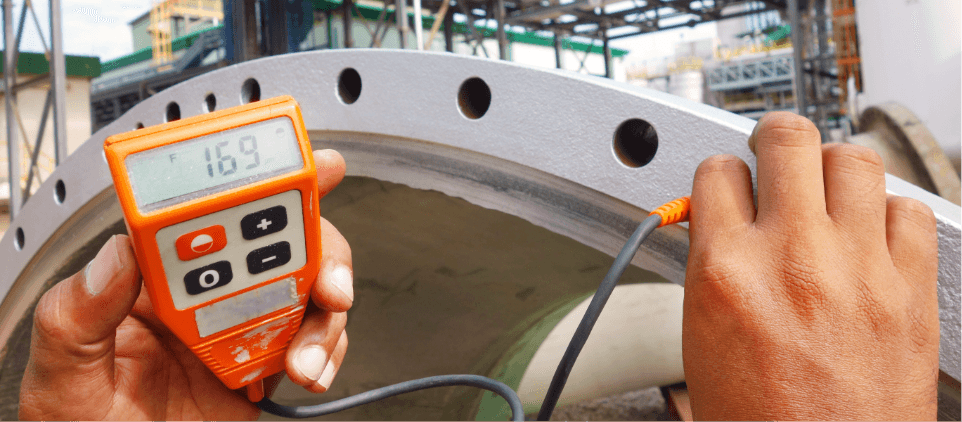

DCC BV has available the equipment to measure gloss levels at the specified angles.