Inspection

Inspection is the method to determine to what extent explicit specifications requirements are met. DCC has professional certified coating inspectors with decades of experience. A DCC inspector relies exclusively on facts, not on opinions.

Performing coating inspections is one of our main activities. Coating inspections are carried out on behalf of asset owners, paint suppliers and contractors in both the Netherlands and other countries.

Coating inspections are performed to make sure that the work is carried out in accordance with the previously agreed terms and conditions. Despite the fact that quality certification according to ISO 9000 has become common in the industry, it is our experience that independent quality control is very important and provides a substantial contribution to the final quality of a project. DCC employs a number of NACE level 3 certified coating inspectors. Carrying out inspections requires professional knowledge, experience, and above all, communication skills. Our approach is always solution-oriented. DCC has experience with projects that are carried under Norsok M501 or other standard specifications issued by the large petrochemical companies such as Total, Shell, ExxonMobil, etc.

Inspection or surface preparation

A thorough surface preparation of a substrate is essential for the performance of a coating system. It can best be compared with the foundation of a building. If the foundation is not solid, the building’s integrity will…

Climate conditions

The correct climatic conditions at the moment of paint application is of great importance for the performance of the paint system as such. It is widely known that the climate conditions under which a product is applied…

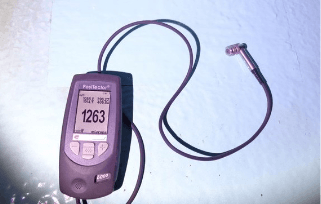

Dry film thickness

Degree of cure

Achieving sufficient or even full curing of a coating system is essential in order to determine the correct moment to put a coating or lining system “into service”. The degree of cure is linear to the achieved strength…

Pinhole detection

If a coating shows pinholes, the resistance to diffusion at these locations is not optimal. Pinholes are often difficult to detect visually. DCC tests the coating or lining on the presence of pinholes using a pinhole…

Adhesion

Whether a coating system has a cosmetic or protective function, if it does not sufficiently adhere to the substrate, the intended function cannot be guaranteed. When a coating system does not adequately bond…

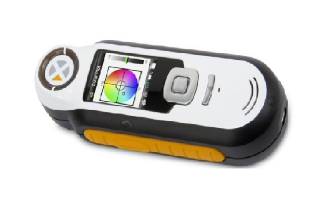

Measuring colour and colour differences

In many cases the color of a coating system is important. Is the color of the coating the agreed color? Is there so-called “discoloration”? DCC can assist you. Colour and perception of colour is often…