Chromium 6 in coating systems

Hexavalent chromium is found in certain old coating systems. It poses a significant risk to those who have to remove this type of coating.

It will not have escaped anyone’s notice that there has been a lot of news recently about the risks of Chromium 6 (6 chromium worthy). In the past, Chromium 6 was used as part of the color pigmentation but also the anti-corrosion pigmentation in a large number of paint products. These would typically be pigments such as lead chromate, zinc (tetra-oxy) chromate, etc.

The use of Chromium 6 has come to a complete halt in most countries from the year 2000, with the exception of specific applications for the aviation and defense industries.

Chromium 6 can still be found in many places as part of existing coating systems. It is sometimes forgotten that Chromium 6 has also been used frequently as a so-called “conversion layer” prior to the application of paint or powder coating on, for example, aluminum or hot-dip galvanized steel.

The presence of Chromium 6 in paint does not in itself pose an immediate risk. Only when we start “machining” the old paint, in other words sanding, scraping or blasting, does a risk of exposure arise.

It is therefore important to have the presence of Chromium 6 analyzed when there is an intention to process or remove the old paint.

DCC BV always combines an analysis for the presence of Chromium 6 with an analysis for heavy metals. The focus on chromium 6 is sometimes so strong that the presence of other components (pigments) in paint also posing an equally great risk to the environment and health is overlooked. It frequently happens analysis show samples not to contain no chromium 6 but do contain very high concentrations of lead. A second reason is that the presence of high concentrations of zinc or other element “disturb” the chemical reaction indicating the presence of Chromium 6 and therefore making it technically impossible to specifically detect chromium 6. If “total chromium” (as a chemical element) appears to be present, the paint will still be regarded as suspect and possibly containing Chromium 6.

The analysis of the paint consists of a sample being taken from the coating system to be tested. The samples are analyzed in a laboratory for the presence of the following heavy metals;

- Arsenic

- Cadmium

- Chromium (total)

- Copper

- Lead

- Mercury

- Nickel

- Selenium

- Zinc

This analysis of heavy metals (elements) is performed using ICP-OES (Inductively Coupled Plasma – Optical Emission Spectrometry).

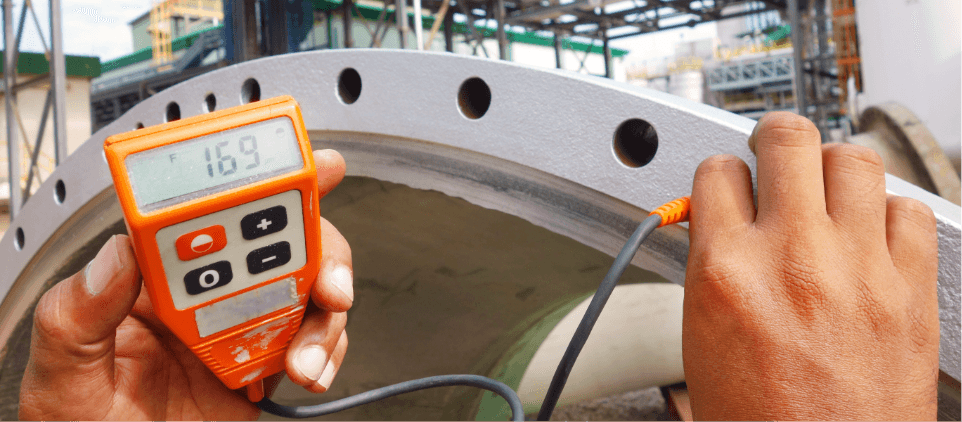

Heavy metal analysis can also be performed using an XRF handheld scanner. This scanner makes it possible to analyze a paint layer for the presence of heavy metals on location. This scanner is however not able to detect specific Chromium 6 and can only find “total chromium” as a common element. For a specific chromium 6 analysis, a separate analysis will then have to be performed. The device is as such unsuitable for the analysis of chromium 6.

It is possible to demonstrate Chromium 6 qualitatively on location by means of a so-called “swab test”. In this test, a liquid is used that gives a discoloration reaction with specific Chromium 6. The disadvantage of this method is that the discoloration reaction can sometimes not be determined unambiguously, especially when the natural color of the product / paint layer to be tested is very close to the color of the indicative reaction discoloration. So there is a risk of a “false negative” or “false positive” result.

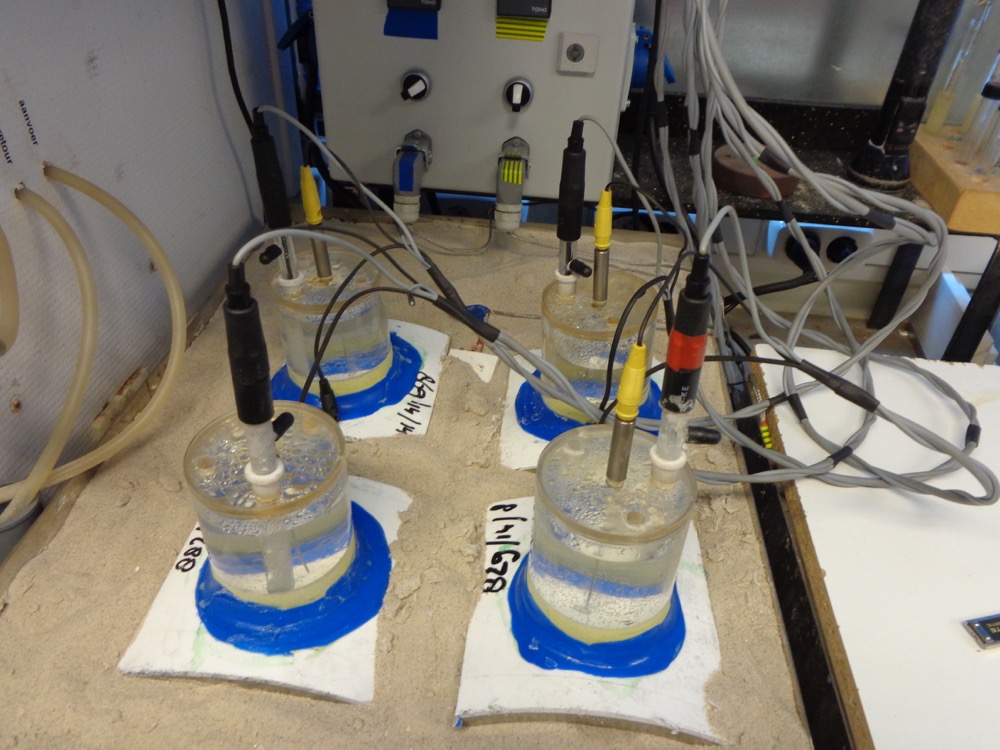

With regard to the specific analysis of chromium 6, DCC BV prefers a lab analysis based on sample of material that is removed on location. The quantitative analysis of Chromium 6 is performed by Soluble Ion Analysis using a Discrete Analyzer. This method is based on a discoloration reaction with diphenyl carbazide based on calorimetry. The results of the analysis are given in mg / kg.

The above analysis identifies a possible presence of chromium 6 and other heavy metals. As of 2017, the Dutch RIVM has set the legal limit (the maximum permitted concentration on an 8-hour working day) for easily soluble chromium 6 compounds in the air at a workplace to 10,000 nanograms of chromium-6 / m³. (= 1 µg / m3). For poorly soluble chromium 6 compounds, the legal limit value for the workplace is 50,000 nanograms of chromium-6 / m³ (= 5 µg / m3).

There is no direct relationship between the degree to which chromium 6 is present in a coating system and the degree of exposure. The actual degree of exposure is very much depending on the way in which the chromium 6 containing coating is processed and the conditions under which this takes place.

In general, during the processing of chromium 6-containing coatings, material should be collected as much as possible at the source, for example by means of dust extraction.

The requirements as indicated in the “Checklist-Chroom-6-in-oppervlakken” issued by the Dutch authority “Inspectie SZW” are to be followed. Also see inspectieszw.nl