Degree of cure

Achieving sufficient or even full curing of a coating system is essential in order to determine the correct moment to put a coating or lining system “into service”. The degree of cure is linear to the achieved strength of a coating system.

The degree of cure of a coating system is an important parameter during inspection as well. When a coating system has not sufficiently cured it is more sensitive to mechanical influences such as scratching, impact, or pressure. In case of a lining insufficient curing will also result in extreme damage to the coating system due to chemical attack (softening), blistering or contamination of the cargo. Such failures almost always result in the need to completely replace the lining and in extreme cases loss of the cargo due to contamination. Both are obviously costly and time consuming. DCC has the knowledge, experience and equipment to measure the rate of cure of coating systems and to correctly assess the results based on the requirements of a coating specification or requirements from the coating manufacturer. A proper coating specification will provide guidelines in the way of test methods and criteria for acceptance/rejection of results. Click here for an overview of the most common methods for the evaluation of the rate of cure.

Common test methods ‘degree of cure’

The durability of a coating system depends on the rate of cure of that coating system at the point where it is been put into service. The following are the most common test methods to measure the degree of cure of industrial coating systems:

- MEK Rub test according to ASTM D4752 to measure the degree of cure of inorganic zinc silicate products (IOZ). The solvent MEK (Methyl Ethyl Keton) is used to determine the resistance of the coating to be tested against being “dissolved” . The standard contains a reference that identifies the various stages of cure of the coating based on the degree to which it has dissolved after being rubbed with a MEK saturated cloth.

- Solvent test according to ASTM D5402 to measure the degree of cure of organic coatings. A solvent from a type to be determined, is used to determine the resistance of the coating to be tested against being “dissolved” The standard contains a reference that identifies the various stages of cure of the coating based on the degree to which it has dissolved after being rubbed with a solvent saturated cloth.

- A theoretical assessment of the degree of cure by using data provided by the coating manufacturer. Parameters such as film thickness, climate conditions, surface temperature during curing and curing time of the relevant product are necessary. A practical problem is that usually there is no full insight in the surface temperature and other climate conditions throughout the total curing process, unless a so called data logger has been used to continuously measure and log this information.

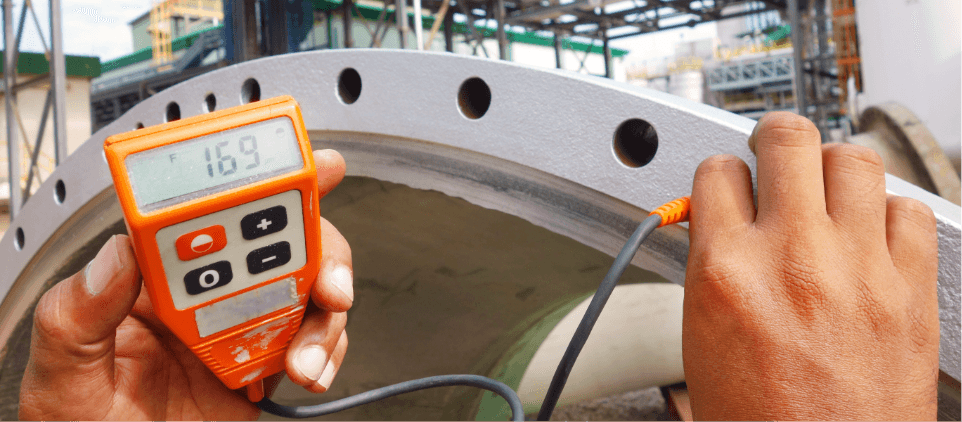

- Assessing the rate of cure by measuring the hardness of the coating film. When a coating film has achieved a specific hardness this is an indication of the degree of chemical cure. When the manufacturer is able to specify the harness of the product at full cure the hardness and therefore the degree of cure can be measured using an impression hardness gage such as a Barcol or Shore gauge.

- Assessing the degree of cure by means of a DSC test (Differential Scanning Calorimetry). This test is a lab test and is not suitable for field measurements.